We have posted a series of columns on Li-ion battery protection ICs on our website.

These columns are written by our battery protection IC specialist.

Will Li-ion Battery Protection ICs Never Perish?

We plan to post blogs about protection ICs that support the safety of Li-ion batteries behind the scenes, including the history of development, application transitions, troubleshooting, and more, along with our past experiences.

In this article of the "Blog+", we will briefly introduce the first column. We hope that you will read the column if you are interested.

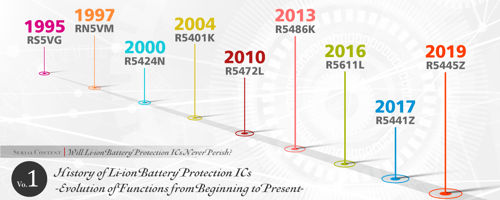

Volume 1 History of Li-ion Battery Protection ICs -Evolution of Functions from Beginning to Present-

★★★

The first column we will introduce in this article is about the history of Li-ion battery protection ICs (the first part).

As you know, Li-ion batteries are secondary batteries that can be recharged multiple times and are widely used of course in mobile devices such as mobile phones, cameras, and PCs, as well as in bicycles and automobiles these days.

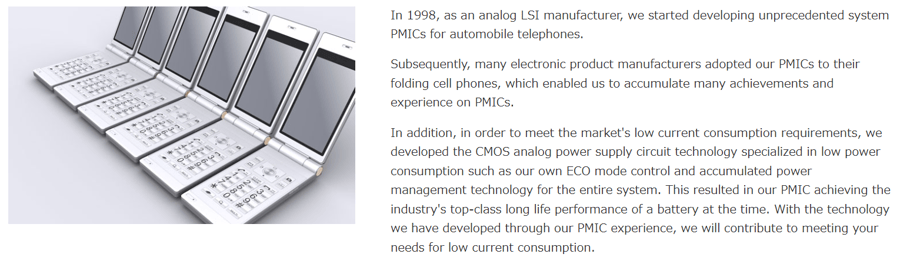

In fact, in the late 1990s, Nisshinbo Micro Devices Inc. (formerly Ricoh Electronic Devices) was the first company in Japan that successfully developed a semiconductor chip called an analog one-chip (AOC) containing almost all analog functions, including power management functions which were required to configure a cell phone system. At the time, more than 40 million mobile phones were sold annually in Japan, and more than 50% of them were equipped with our AOC (now we call them PMICs).

Mobile Phones and Protection ICs

When the leading role of portable communication devices began to shift from pagers to mobile phones in the late 1990s, the history of our PMICs began with the development of system power management ICs for car phones.

From the dawn of the mobile phone industry through its growth to its flourishing period, our protection ICs, like those products of other companies, were also used in mobile phone battery packs.

It has been about 25 years since we developed our first protection IC.

Twenty-five years is a quarter of a century. During that time, many things have happened. Problems have also occurred.

We have overcome these problems with additional features and technological innovations.

Overcharge Detection, Overdischarge Detection, Discharge Overcurrent Detection

Our first product had only three functions of detection: overcharge detection, overdischarge detection, and discharge overcurrent detection.

One of the problems occurred during our customer's evaluation phase due to misunderstandings in specifications of the overcharge detection function.

Having learned from these lessons, we added features to subsequent products.

Learn more about features such as overcharge detection, overdischarge detection, and discharge overcurrent detection.

Li-ion and Nickel–metal Hydride Batteries

In addition, since some models of mobile phones at that time used not only Li-ion batteries but also nickel-metal hydride batteries, we had to account for the differences in these batteries.

Nickel-metal hydride batteries were often used in mobile phones in the past because they were cheaper and easier to use than Li-ion batteries.

However, nickel-metal hydride batteries have memory effect by which their performance degrades after repeatedly recharging partially discharged batteries. Therefore, they were replaced by Li-ion batteries, which have no memory effect and can provide higher capacity than nickel-metal hydride batteries. At present, Li-ion batteries are used as rechargeable batteries in most of the applications which can also adopt dry-cell batteries.

Charging 0-V Batteries and Dendrites

It is interesting to note that in the past there was a difference of opinion between battery manufacturers and set manufacturers, or battery users, on whether to charge 0-V batteries or not.

Since charging a battery discharged to near 0 V could cause an internal short circuit due to formation of dendrites, battery manufacturers wanted to prohibit charging of 0-V batteries. However, set manufacturers were eager to get them recharged since the prohibition would lead to customers' complaints.

Dendrite generally refers to dendritic crystals, but here it refers to lithium metal precipitating in dendritic crystals. When dendrites are formed, they break through the separator (separation membrane) that separates the positive and negative electrodes in the cell. This causes an internal short circuit and in the worst case thermal runaway in batteries, which is a very dangerous situation.

Further Accuracy Improvements and Additional Features

As time progressed and battery performance improved, safety awareness also grew. Accordingly, we added new protective functions and improved detection accuracy.

In the 2000s, we introduced a product that allowed setting all delay times by a built-in counter, eliminating the need for a delay capacitor, and reducing costs for our customers. This product also made it possible to shorten test time by adding a test terminal.

We also proposed methods to improve the accuracy of overcurrent detection by using external resistors. In addition, other functions and features our protection ICs acquired in the 2000s include: multi-step overcurrent detection to detect overcurrent more precisely; a reset pin to control the protection IC externally; and a temperature protection function.

In 2019, a standby pin was installed. By setting this pin to "L", the current consumption was reduced to almost zero, preventing the battery from being depleted by the current consumption of the protection IC after the battery pack was manufactured and before it reached end users.

Click here for Nisshinbo Micro Devices' Li-ion battery protection ICs.

Thus, as the ages have passed, both Li-ion batteries and battery protection ICs have evolved in accordance with the demands of society.

We hope you will read this column to learn the history of such protection ICs.

Volume 1 History of Li-ion Battery Protection ICs -Evolution of Functions from Beginning to Present-

Comment